Inter-Integrated Circuit (I²C) Debugging and Error Handling#

Use this section to troubleshoot Inter-Integrated Circuit (I²C) on SiWx917. You’ll perform quick hardware checks, debug on the development kit, capture SDA/SCL with a logic analyzer, and apply driver-level recovery steps while interpreting common error codes.

Common Debugging Tips#

See the official troubleshooting guide for application-level debugging: WiSeConnect Debugging Guide.

Debugging I²C Connections#

Debugging typically starts with wiring and compatibility checks, then moves to tool-assisted verification with Simplicity Studio and a logic analyzer.

1. Visual Inspection and Connection Checklist#

Before running software tests, verify:

SDA/SCL wiring is correct between the leader (controller) and follower (target).

Pull-up resistors are present on both lines (commonly 4.7 kΩ–10 kΩ; lower values for higher speeds/longer buses).

Common ground connects all boards.

I/O voltage levels are compatible on both sides (for example, 3.3 V or 1.8 V).

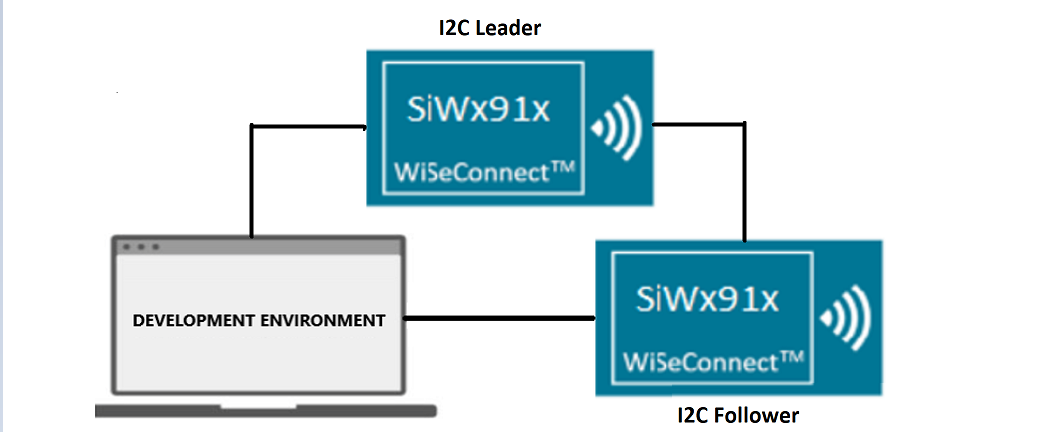

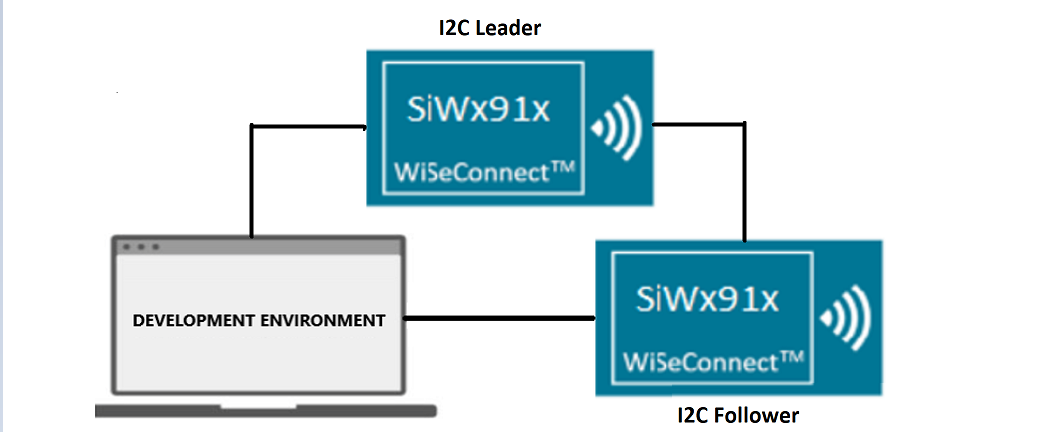

2. Interfacing with Si91x Development Kits (Leader/Follower)#

Si91x development kits make I²C bring-up straightforward. Use one board as the leader (controller) and another as the follower (target).

Setup steps:

Connect SDA to SDA and SCL to SCL between boards.

Ensure a shared ground and power both boards.

Use Simplicity Studio to flash and debug firmware on each board.

Run I²C transactions; monitor with a logic analyzer and Simplicity Studio’s debug tools.

For custom followers, confirm the address and timing (speed/clock stretching) match the leader’s configuration.

Example setup diagram:

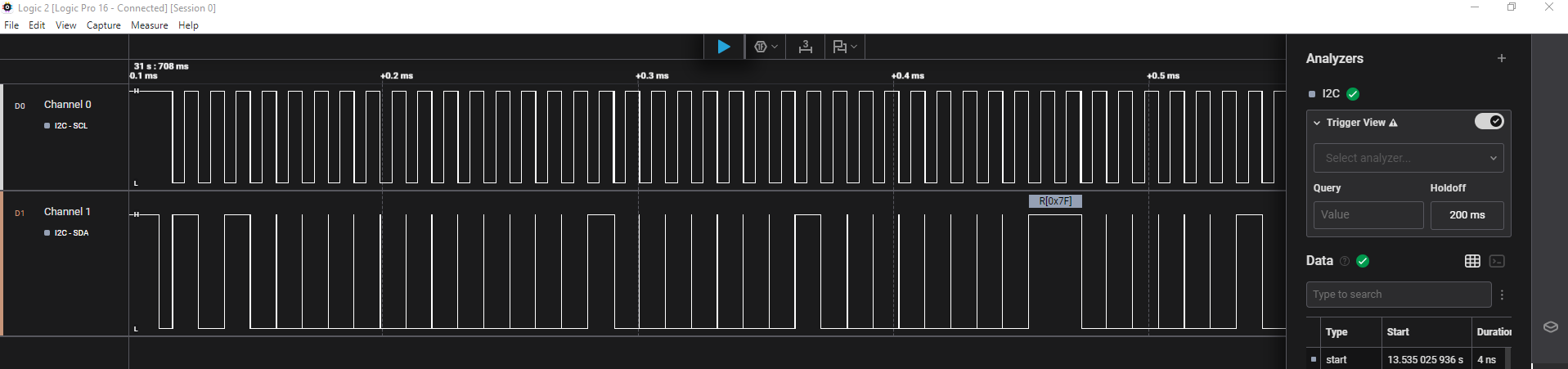

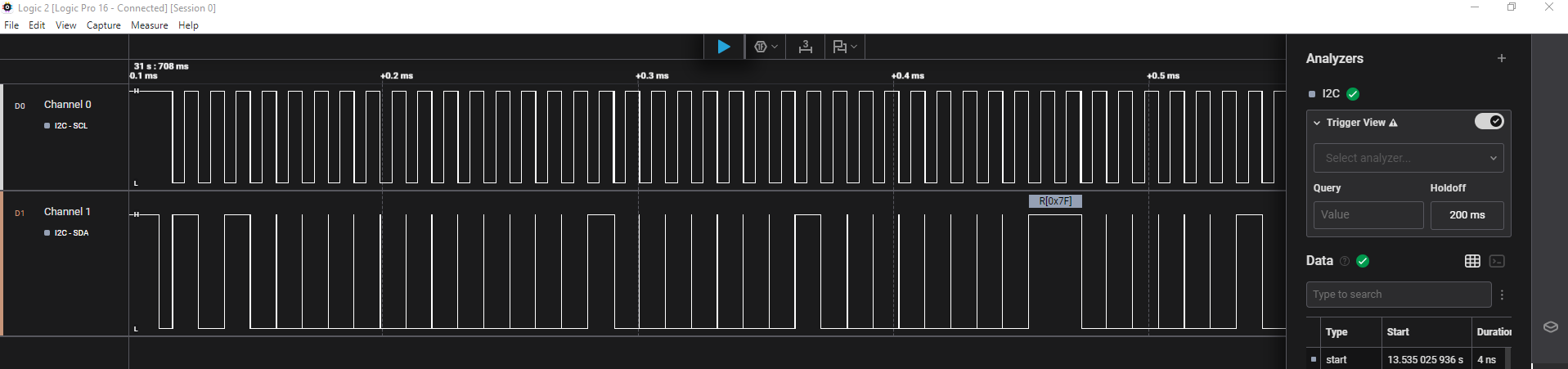

3. Using a Logic Analyzer#

A logic analyzer lets you view I²C waveforms and decoded protocol frames.

Steps:

Attach probes to SDA and SCL.

Enable I²C protocol decoding; set a suitable threshold and a sample rate of at least 1 MHz.

Capture typical transactions and verify:

START/STOP conditions

Address + R/W and subsequent ACK/NACK

Data bytes and expected repeated START (when required)

Clock stretching behavior

Example capture:

The following capture (Saleae Logic Pro 16) shows I²C between two Si91x boards configured as leader and follower using a blocking-transfer example.

4. Simplicity Studio + Logic Analyzer Workflow#

Correlate firmware execution with captured bus activity:

Open Simplicity Studio and switch to the Debug perspective.

Program firmware and connect the logic analyzer to SDA/SCL.

View I²C signals in the analyzer app (or Studio plug-in, if available).

Place breakpoints to align code paths with on-wire frames.

Error Code Handling#

The I²C driver returns standardized status codes from APIs.

The driver returns sl_i2c_status_t values. Common ones include:

Status | Meaning |

|---|---|

| Operation completed successfully |

| Not-acknowledge received |

| Bus error detected |

| Transfer complete |

| Controller is idle |

Use these to identify issues such as bus lockups, mis-wired pins, or timing mismatches.

If the peripheral enters an error or undefined state (for example, missed ACK, contention, or after a power transition), reset the driver:

sl_i2c_driver_deinit();

sl_si91x_i2c_init();Additional Debugging Tips#

Use these practices to improve debugging:

Print error codes and status messages in firmware with

DEBUGOUT.Check for bus contention, shorted lines, or missing pull-ups if communication fails.

Diagnose timing issues, missed ACKs, or unexpected NACKs with a logic analyzer.