Pulse Code Modulation (PCM) Debugging and Error Handling#

This section describes how to debug Pulse Code Modulation (PCM) connections and handle driver-level errors on the SiWx917 platform. It covers recommended hardware setup, signal inspection, logic analyzer usage, and recovery techniques for common PCM issues.

Common Debugging Tips#

Before debugging PCM-specific issues, review the official application-level guide for general debugging best practices:

WiSeConnect Debugging Guide.

Debugging PCM Connections#

Debugging typically starts with basic wiring inspection, followed by signal analysis using a logic analyzer and Simplicity Studio debug tools.

1. Visual Inspection and Connection Checklist#

Before using software debugging tools, verify physical connections:

Confirm Frame Sync (FSYNC), Bit Clock (BCLK), and Data (DIN/DOUT) lines are correctly connected between devices.

Ensure common ground between all connected boards.

Verify voltage compatibility between devices (for example, 1.8 V or 3.3 V).

Check for stable and clean clock signals using an oscilloscope or logic analyzer.

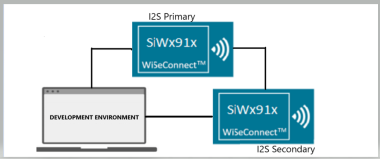

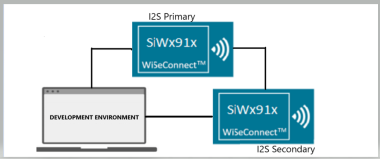

2. Interfacing with Si91x Development Kits (Primary/Secondary Setup)#

Use Si91x development kits for bring-up and debugging. Configure one board as the primary and another as the secondary.

Setup Steps#

Connect FSYNC, BCLK, and Data lines between the boards.

Ensure a shared ground and power both boards.

Program each board using Simplicity Studio.

Run PCM transactions and observe results using a Logic Analyzer (LA).

For custom secondary devices, verify that frame format, polarity, and sample rates match the primary device configuration.

Example Setup Diagram#

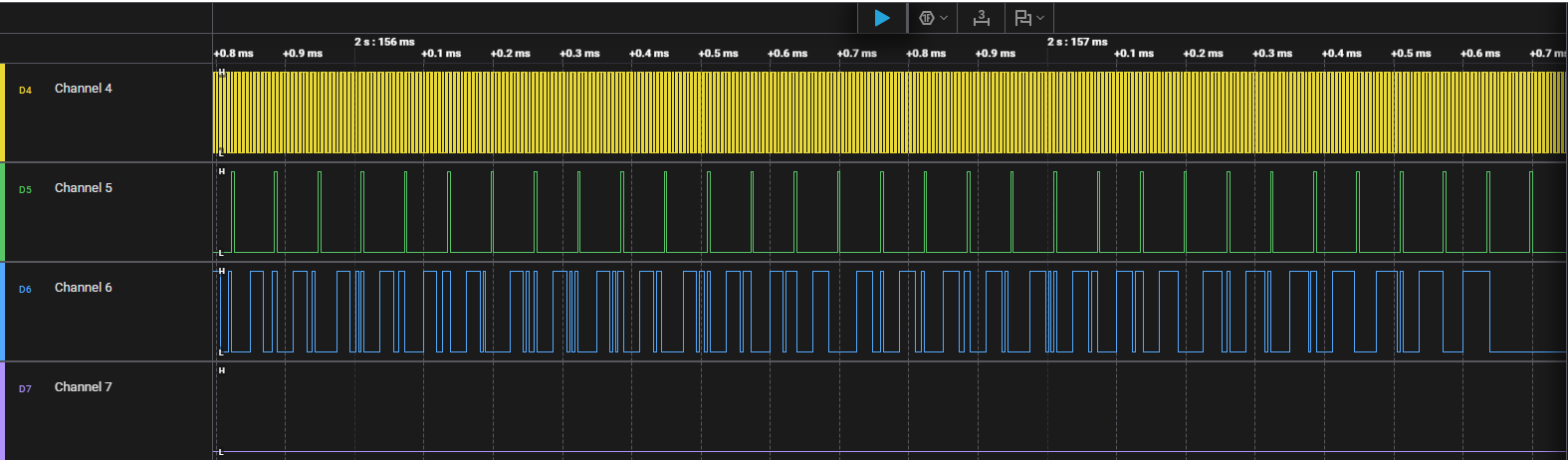

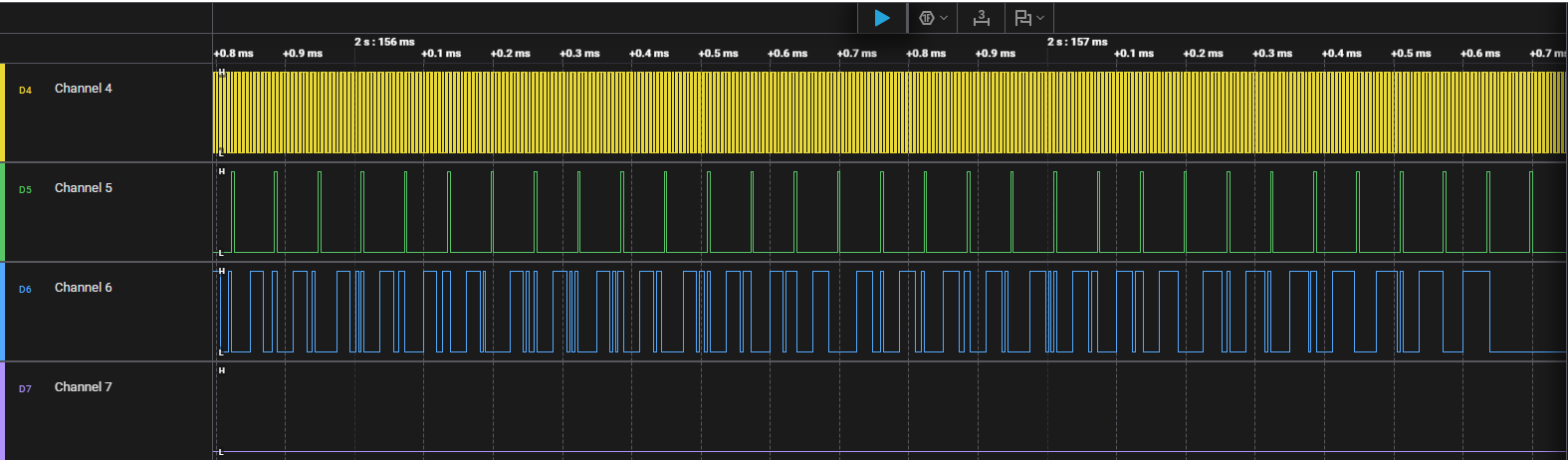

3. Using a Logic Analyzer#

A Logic Analyzer provides detailed visibility into PCM signals. Use it to confirm correct timing, alignment, and waveform integrity.

Setup Guidelines#

Connect probes to BCLK, FSYNC, and Data lines.

Enable PCM or I²S decoding in the analyzer software.

Set an appropriate threshold voltage and a minimum sample rate of 1 MHz.

Capture and validate:

Frame sync polarity and width.

Bit clock frequency and duty cycle.

Data order and word alignment (MSB-first or LSB-first).

FIFO underrun/overrun timing and interrupt response.

Example Capture#

4. Simplicity Studio Debug Integration#

Simplicity Studio can correlate firmware execution with Logic Analyzer data for deeper insight.

Workflow#

Open Simplicity Studio and select the Debug perspective.

Flash firmware and connect LA probes to PCM signal lines.

Capture PCM waveforms using the LA plug-in or an external analyzer.

Place breakpoints in your code to correlate execution with frame transitions.

Error Code Handling#

The PCM driver returns standardized status codes through APIs such as sl_si91x_pcm_transfer() and sl_si91x_pcm_receive(). These indicate operation success, errors, or hardware states.

Error Code | Description |

|---|---|

| Operation completed successfully. |

| General failure occurred. |

| Operation timed out (check clock or FSYNC). |

| Invalid configuration or argument provided. |

| PCM peripheral or DMA is busy. |

| PCM peripheral not initialized before use. |

If PCM enters an undefined or error state (for example, frame misalignment, clock loss, or FIFO underrun/overrun), perform a driver reset:

sl_si91x_pcm_deinit();

sl_si91x_pcm_init();Additional Debugging Tips#

Use the following best practices to accelerate PCM troubleshooting and ensure reliable audio operation on the SiWx917 platform:

Enable runtime logging:

UseDEBUGOUTstatements to print error codes, status messages, and callback events during PCM operation. This helps trace the exact point of failure.Verify signal integrity:

Confirm clean BCLK, FSYNC, and Data (DIN/DOUT) lines with a logic analyzer or oscilloscope. Look for missing edges, jitter, or inconsistent clock frequency.Check configuration consistency:

Ensure that both primary and secondary devices use the same sample rate, data width, and frame-sync polarity. Mismatched configurations commonly cause framing errors or distorted audio.Use DMA for continuous streaming:

Enable DMA-based PCM transfers to minimize CPU intervention and reduce the risk of underruns or overruns during real-time playback or recording.Adjust FIFO thresholds:

Fine-tune FIFO trigger levels for optimal balance between latency and throughput. Higher thresholds help avoid underruns in long data streams.Correlate firmware and hardware events:

Use Simplicity Studio’s Debug perspective in combination with a logic analyzer to align breakpoints with PCM frame events for root cause analysis.Monitor for underrun and overrun errors:

Add event-handling logic in callbacks to detect and respond to FIFO underruns and overruns. Use these logs to optimize buffer size and interrupt priority.Inspect clock domain stability:

Ensure the PCM peripheral’s clock source is stable and active throughout the operation, especially when switching between power states (PS3 ↔ PS4).Reinitialize after low-power transitions:

After waking from deep-sleep states, callsl_si91x_pcm_init()to reconfigure the PCM peripheral and restore synchronization.Use reference examples as baselines:

Start from the WiSeConnect SDK PCM examples (Primary, Secondary, Loopback) before customizing. These examples include verified configurations for timing and DMA setup.

Tip: To maintain consistent audio quality, always validate PCM timing using a Logic Analyzer when modifying frame size, sample rate, or polarity.