Effect of the Production Calibration the System Crystal#

How to Adjust the System Crystal describes how to remove the frequency offset of a product. This will ensure that the system frequency error is reduced to ±1ppm.

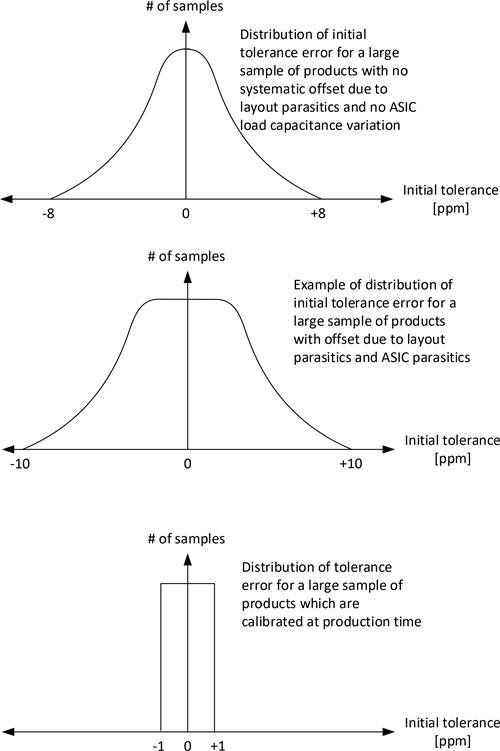

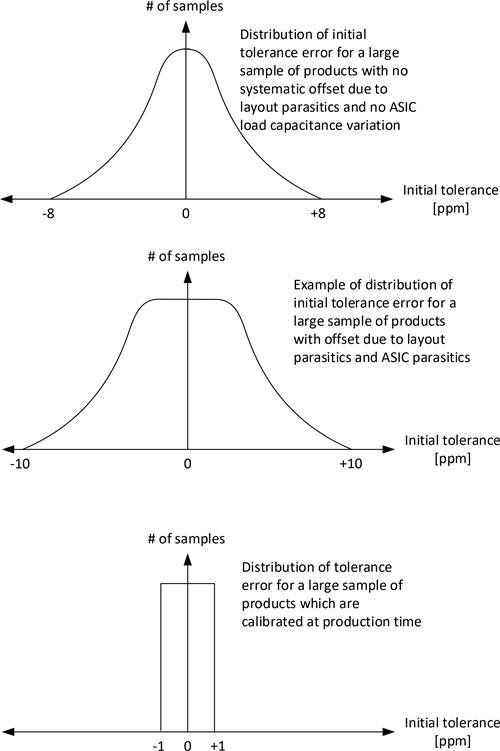

When each product is production calibrated, the net result will be as shown below.

As seen from the figure above, the initial crystal tolerance is at ±8 ppm, and the offset due to layout parasitic and Z-Wave SoC variance is reduced to e.g., ±1 ppm since each product is individually measured and calibrated.

To sum up: to individually calibrate each product item, one must:

Be able to download RAILtest during the manufacturing of the product

Be able to control RAILtest during the manufacturing of the product

Be able to precisely measure a CW from the product with a precision of ±1 ppm

With the aid of a spectrum analyzer or an RF frequency counter

Be able to derive a CTune value from the frequency measured

Be able to incorporate the CTune value found into the Z-Wave protocol code to download

As seen in the procedure description above, the CTune value found must be incorporated into the Z-Wave protocol. This is done in the form of a TOKEN_MFG_CTUNE value, with value = CTune, which is programmed into memory according to the description provided in [2].